LSD Binder Jetting

LSD Binder Jetting

Combining the Layerwise Slurry Deposition with 3D printing is a logic extension of powder based 3D printing technologies. Instead of spreading a dry powder into thin layers, a ceramic slurry or slip is used in order to increase the powder packing density in the powder bed. For the buildup of 3D structures the process steps layer deposition, drying, and 3D printing are repeated. Typical layer thicknesses are between 50 and 100 µm.

After deposition of all layers required for building up the desired geometry, the laser sintered or printed body is embedded in the powder bed which now is a block of densely packed particles. For the release of the part, the powder compact must be dissolved by a solvent. In case water based slurries are used for the layer deposition, water can act as a solvent for the powder bed.

The use of a ceramic suspension for layer deposition in additive manufacturing is an upcoming technology, and only few results are available. The advantage of slurry based layer deposition is its potential to produce powder compacts with high powder packing densities, typically exceeding 55% TD. For the manufacture of a powder compact with properties comparable to those produced by classical powder processing, LSD based 3D printing has a high potential. By the use of small amounts of organic or inorganic binders provided by a printing head, the particles in the densely packed powder bed are locally glued together, and compacts generated by this technology don’t require any additional treatment prior to sintering.

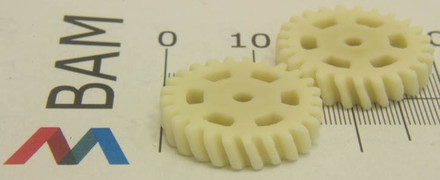

Figure 1: Parts made by the LSD based 3D printing: material Almatis CT3000SG, green density 2.32 g/cm3, sintered at max. T of 1600 °C, final density3.94 g/cm3 [1].

Figure 2: Parts made by the LSD based 3D printing: material SiC.

Materials

With the following material parts have been manufactures successfully. Please consider, that parts after laser sintering are not ready to use, but need a post sintering:

Fine Fire Clay

VC / Porcelain

SiC

Al2O3

Literature

- 1 Andrea Zocca, Pedro Henrique da Silva Lima, Jens Günster, "LSD based 3D Printing of Alumina Ceramics", J. of Ceramic Science and Technology, 08 [01] 141-148 (2017)

-

Webmeeting / Webkonferenz | May 02 - May 2, 2022

Webmeeting / Webkonferenz | May 02 - May 2, 2022

AKK-Frühjahrstagung 2022 -

Ausschuss / Arbeitskreis | Jun 14

Ausschuss / Arbeitskreis | Jun 14

2. Mitgliederversammlung des Anwenderkreises Keramische Additive Fertigung in der DKG (AKF) -

Webmeeting / Webkonferenz | Jun 17

Webmeeting / Webkonferenz | Jun 17

DKG-Hauptversammlung 2022 -

Webmeeting / Webkonferenz | Jun 17

Webmeeting / Webkonferenz | Jun 17

FDKG-Hauptversammlung 2022 mit Vorstandswahl (Wahlperiode 2022-24)