Multi Material Jetting (MMJ)

Multi Material Jetting (MMJ)

Autor

- Dr.-Ing. Tassilo Moritz

- Winterbergstraße 28, 01277 Dresden, Germany

Telefon +49 351 2553-7747

Fax +49 351 2554-197 - E-Mailtassilo.moritz@ikts.fraunhofer.de

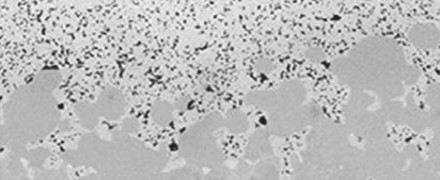

Thermoplastic 3D-Printing (CerAM T3DP) is an Additive Manufacturing method for ceramic components which works material independent and which can be used for manufacturing of multi component and/or functionally graded parts. The technology bases on usage of particle filled thermoplastic feedstocks with low melting temperature (80 – 100 °C). The viscosity of the feedstock is relatively low compared to pure thermoplastic materials which are used for the conventional Fused Filament Fabrication (FFF).

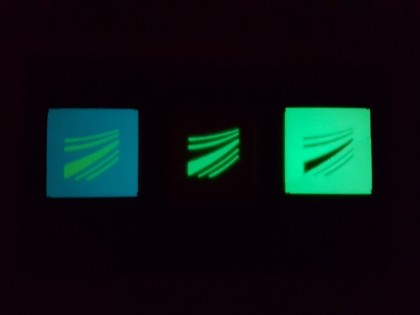

By CerAM T3DP building material is only deposited dot-wise where it is needed for the desired component. A heatable dispensing unit which can be controlled in x-y-z-direction moves above a fixed building platform. The thermoplastic feedstock is molten in a cartridge and deposited as small droplets by a piezo driven micro dispensing unit onto the building platform where they solidify immediately. This behavior makes the process almost independent from the powder properties and allows for building components of ceramic, metal, hard metal or glass powders. Furthermore, by applying two or three dispensing units materials with different properties, polymeric supporting structures or sacrificial structures can be deposited simultaneously.

Multi component glass part consisting of differently colored fluorescing glass powders (Source: Fraunhofer IKTS)

Individualized watch bezel consisting of white and black zirconia printed by CerAM T3DP (Source: EU-Project CerAMfacturing, GA No. 678503)

-

Webmeeting / Webkonferenz | May 02 - May 2, 2022

Webmeeting / Webkonferenz | May 02 - May 2, 2022

AKK-Frühjahrstagung 2022 -

Ausschuss / Arbeitskreis | Jun 14

Ausschuss / Arbeitskreis | Jun 14

2. Mitgliederversammlung des Anwenderkreises Keramische Additive Fertigung in der DKG (AKF) -

Webmeeting / Webkonferenz | Jun 17

Webmeeting / Webkonferenz | Jun 17

DKG-Hauptversammlung 2022 -

Webmeeting / Webkonferenz | Jun 17

Webmeeting / Webkonferenz | Jun 17

FDKG-Hauptversammlung 2022 mit Vorstandswahl (Wahlperiode 2022-24)